Our Solutions

Eddy Current Testing (ECT)

Eddy Current Testing is ideal for inspecting conductive materials without damaging the surface. With real-time results, it efficiently identifies cracks, corrosion, and material degradation, ensuring your assets stay in peak condition.

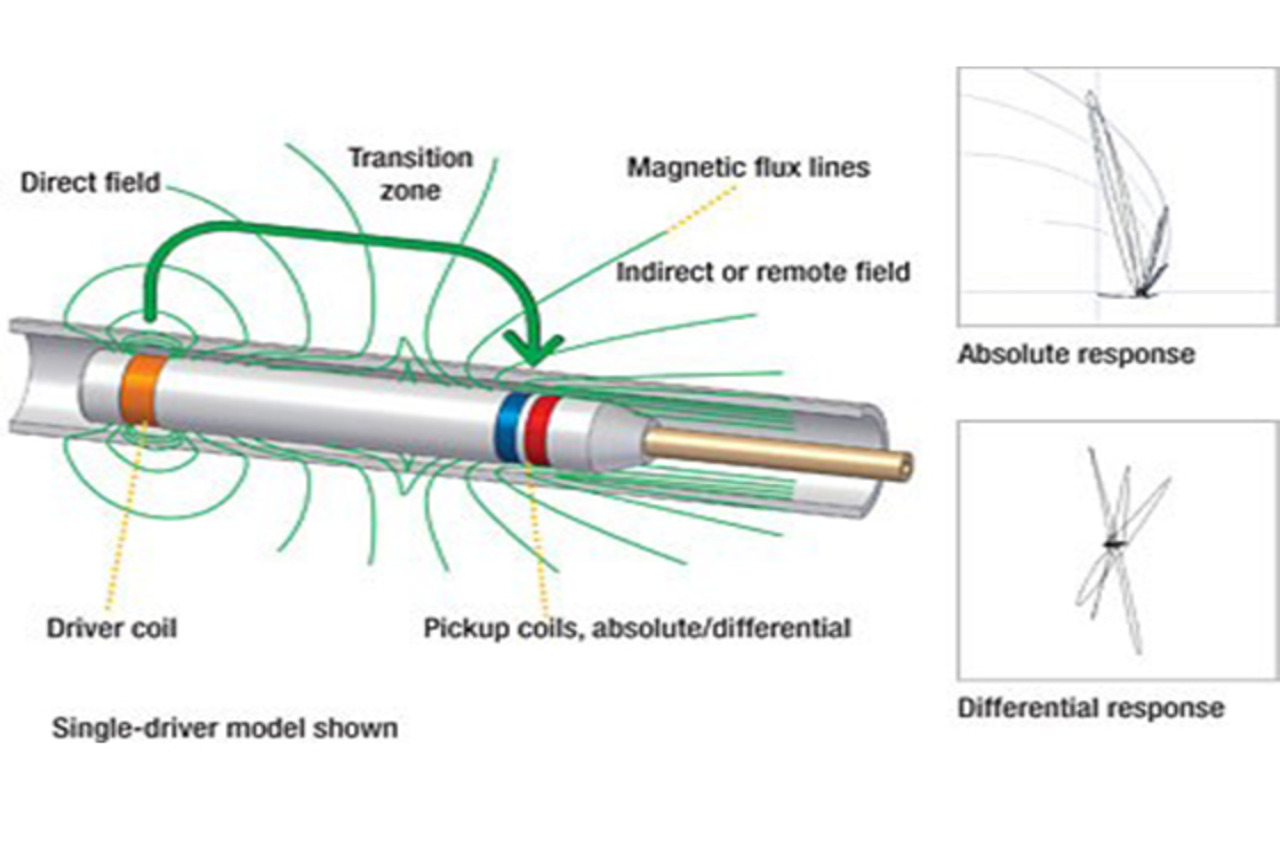

Remote Field Testing (RFT)

RFT offers reliable inspection of ferromagnetic tubing, such as in heat exchangers and boilers, detecting flaws deep within the material walls. Its advanced capabilities ensure precise evaluation of tube integrity, even through thicker materials.

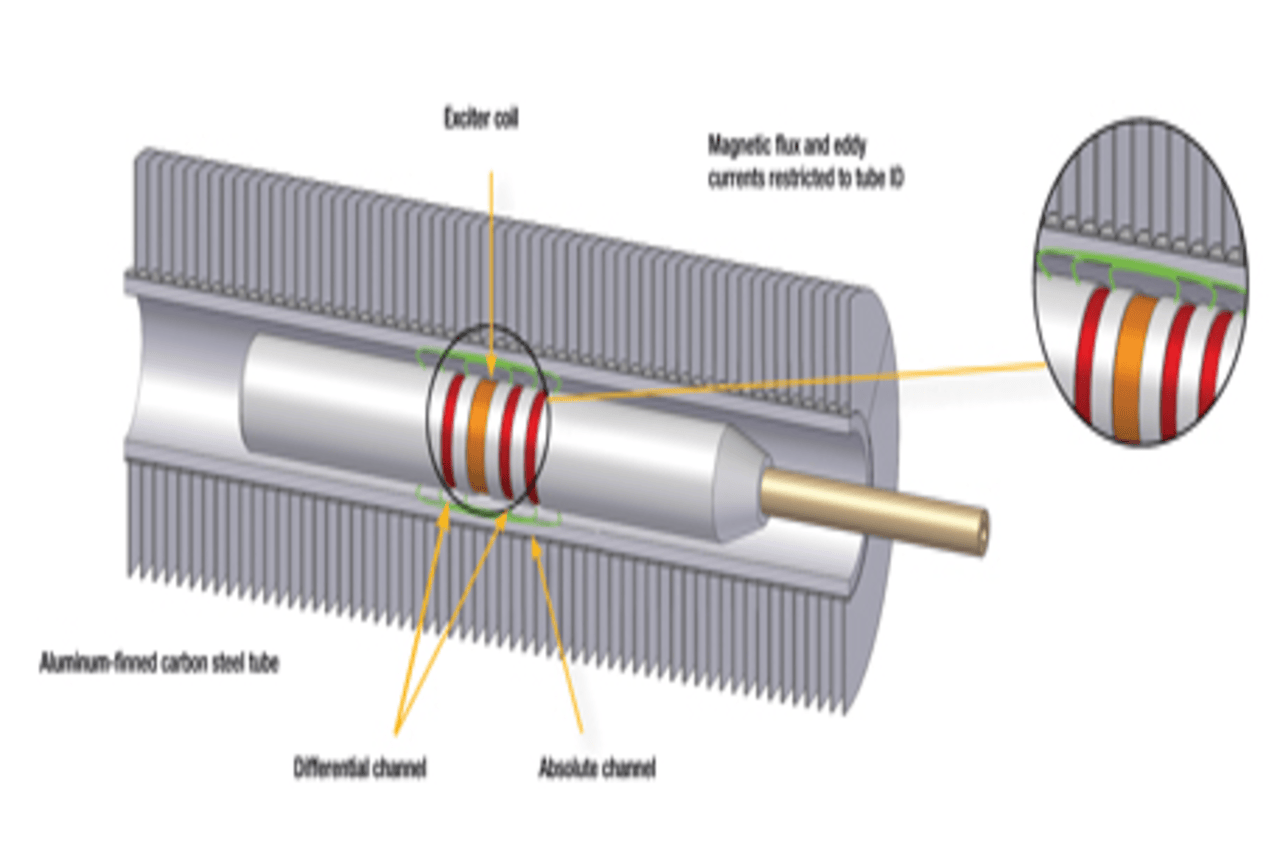

Near Field Testing (NFT)

NFT is designed for non-ferromagnetic materials, such as air coolers and heat exchanger tubing. It provides accurate detection of internal corrosion and thinning, delivering results quickly without the need for complex calibration.

Internal Rotary Inspection Service (IRIS)

IRIS uses ultrasonic technology to deliver detailed, high-resolution images of tubing walls. Ideal for applications requiring precision, IRIS detects pitting, wall loss, and corrosion with exceptional accuracy, ensuring thorough integrity assessments.

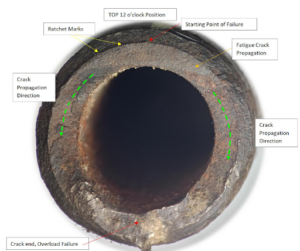

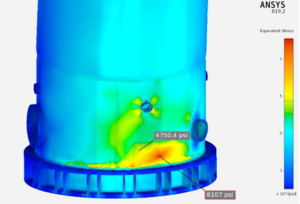

Customized Repair Strategy and Structural Integrity

Customized Repair Strategy and Structural Integrity