Short Range Ultrasonic Technique (SRUT) was designed mainly to test the Annular Plate of Above Ground Storage Tanks (AST’s) while the tank remains in-service, finding out Corrosion Under Pipe Supports, corrosion at soil air interfaces, and similar difficult to access locations. The technique is based on the concept of pulsing guided laminar waves into the base material from the chime area. The waves propagate up to three feet into the annular plate. When corrosion, pitting, erosion are present the ultrasonic waves mode convert and are received by the same transducer.

TechCorr were contracted to perform a current health assessment of corrosion located under pipe support saddles on critical piping systems located on one of the offshore platform at Major Oil Production Company.

Scope of Work:

Short range ultrasonic inspection on inaccessible areas of piping under pipe support saddles, as per client request as listed below.

Inspection Summary and Test Results:

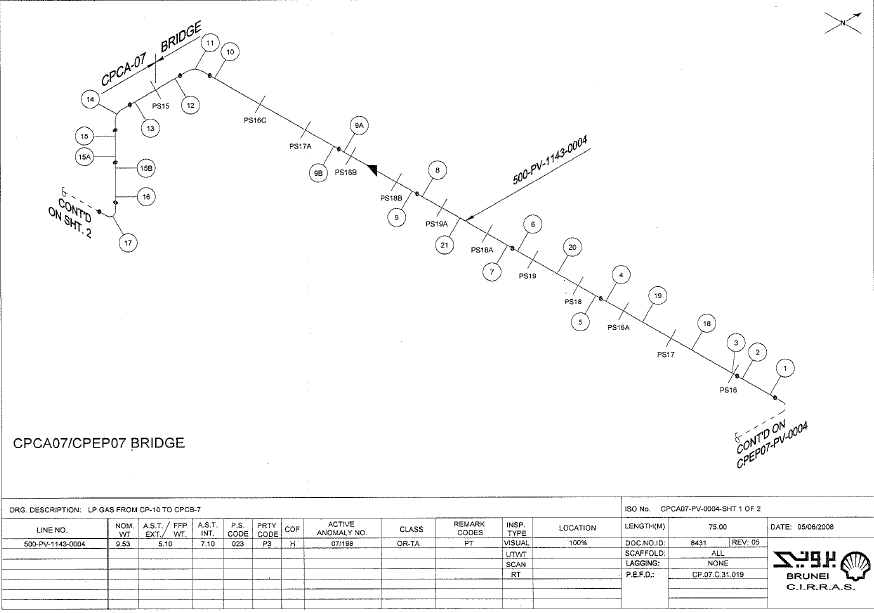

Short range ultrasonic Inspection was carried out on the nine pipe supports as shown in the table below and selective on the scans on the following pages. All areas underneath the pipe supports saddle were fully inspected by Short Range Ultrasonic Testing. Some supports were not cleaned and as a result, only scanned from one side. All scans were carried out in a clockwise direction, if facing east and clockwise if pipe was running north and facing north. The depth of pitting/corrosion could not be obtained, but the area percentage under the pipe support saddle, could be and is given in the table below.

Calibration Scan & Reference Block:

A Calibration scan was carried out on a 300mm x 180mm x 12mm Carbon steel plate, for DAC and sensitivity settings. All reflectors are 1.2mm or 10% of nominal wall thickness.

FIELD SCAN

Support Number: CPCA07-PV-0004-SHT1OF2-PS17A-BOTTOM

Scanning was carried out from East and west sides on bottom pipe Support 17A. Pitting was noted on the piping covered by the pipe support saddle, as Shown in the scan above.

Above scope was completed in 2 days and reports were submitted to the customer before leaving the site. Work was completed with client satisfaction.

PHOTOGRAPHS DURING INSPECTION